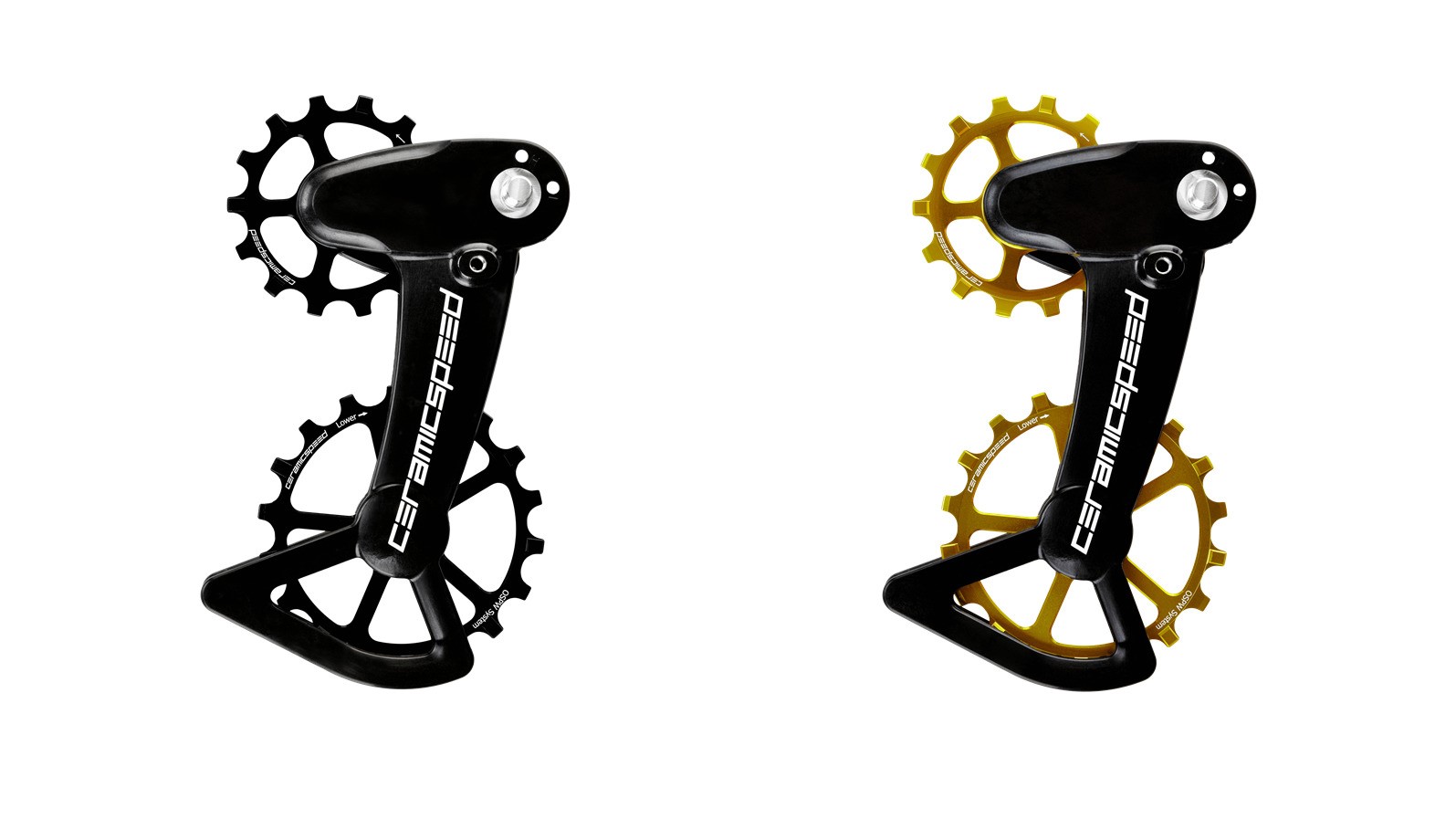

Ceramicspeed's Shimano XTR rear mech

Ceramicspeed has finally added its ceramic bearing wheels to a 12-speed Shimano derailleur

Ceramicspeed has a new upgrade for discerning Shimano mountain biker users.

The Danish low-friction bearing specialist now offers some rather dear rear derailleurs, to match with your Japanese drivetrain system.

For mountain bikers who are consumed with efficiency and the possible loss of power output due to any point of drivetrain friction, Ceramicspeed’s new OSPW X rear derailleur will be the answer they are seeking.

Engineered to work with Shimano’s latest M8100 XT and M9100 XTR 12-speed mountain bike drivetrains, Ceramicspeed’s OSPW X design sees a composite derailleur cage house oversized aluminium pulley wheels.

To ensure convergence the Ceramicspeed OSPW X uses Shimano’s stock chain lengths, features two spring tension settings for alignment, and remains compatible with a generously sized 10-51 rear cassette.

Why would you replace a Shimano factory rear derailleur with Ceramicspeed’s OPSW X system? If watts matter to you, then the Danish system will make sense. Ceramicspeed promises a 35 per cent decrease in drivetrain friction, through their rear derailleur, compared to any standard 12-speed Shimano XTR or XT set-up.

Enabling this gain in drivetrain efficiency are Ceramicspeed’s handmade bearings and the brand’s specially formulated oil. The OPSW X rear derailleur features a 14T upper and 18T lower pulley wheel system.

With smooth-coated ceramic bearings running in your Shimano compatible Ceramicspeed rear derailleur, pricing is €579. Downgrade to the standard Ceramicspeed bearing option and this trick rear derailleur will still cost you €499.

For obsessive endurance riding mountain bikers, drivetrain efficiency is an issue and any reduction in friction is valuable. Unlike road riding, where the Ceramicspeed rear derailleurs are extremely popular amongst triathletes, the mountain bike application appears slightly less ideal.

Off-road riding by its very nature, harvests trail contaminant into any drivetrain, coating the chain and pulley wheels with sediment, which reduces efficiency. By this logic, investing huge amounts on a trick bearing and pulley wheel system, which is exposed to trail dirt and containments, makes a lot less sense, than running Ceramicspeed’s mountain bike bottom brackets.

Lance Branquinho is a Namibian-born journalist who graduated to mountain biking after injuries curtailed his trail running. He has a weakness for British steel hardtails, especially those which only run a single gear. As well as Bike Perfect, Lance has written for MBR.com, Off-Road.cc and Cycling News.